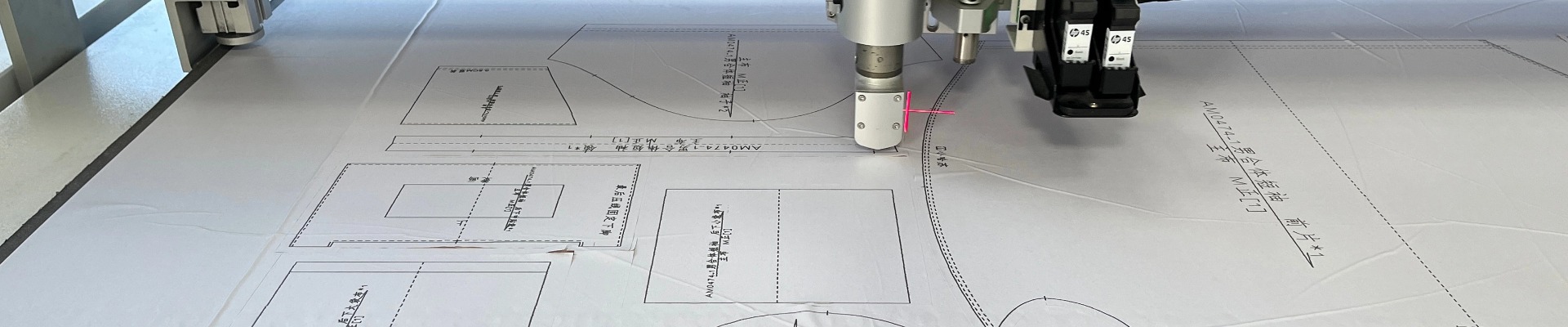

Standardized production

HUCAI has a standardized production process, covering everything from fabric procurement to manufacturing, quality inspection, packaging and logistics. These processes and processes are recorded in detail and continuously optimized and improved to ensure the smooth production process for customers.